Everything you need to know about the storage of goods, from the beginning of the process to how it works.

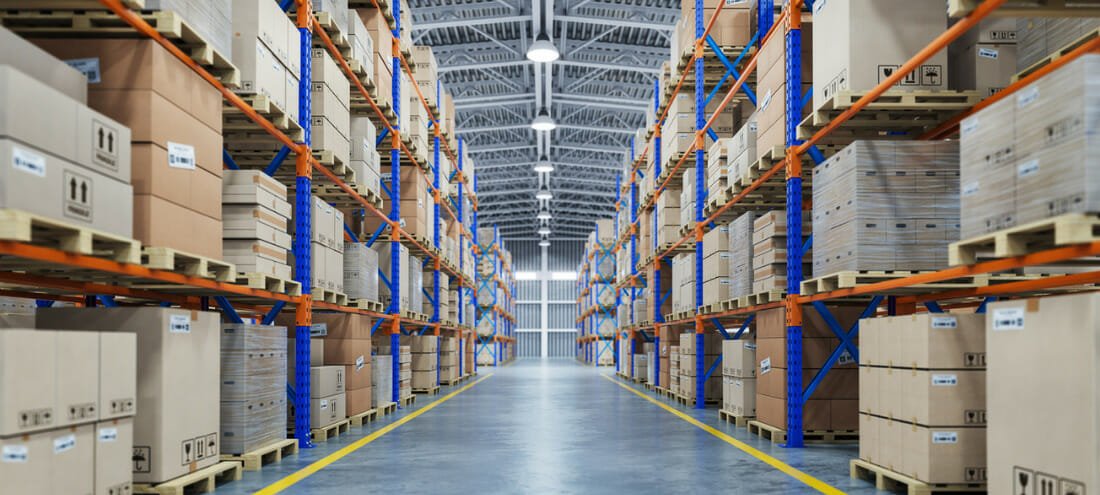

Goods storage is a fundamental activity for the management of supply and distribution within a company’s warehouse. Its main objectives include ensuring the protection of goods from damage, theft, or loss, facilitating the picking and dispatch of goods, and finally, minimising warehouse management costs.

So let’s look in detail at what goods storage is and how it works.

What is goods storage?

Goods storage is the process of managing and storing goods in a warehouse or other storage location. This process involves the professional organisation and storage of goods for a specific period of time to ensure their integrity and availability for sale or distribution.

Goods, depending on their nature, may be stored in warehouses, containers, trucks, refrigerated warehouses, and other appropriate storage locations.

The storage of goods is essential for efficient business operations and for controlling production and logistics costs. It also enables companies to have greater control over the flow of goods and to avoid loss or damage of goods.

How goods are stored

The storage of goods takes place in various ways depending on the type of goods and the needs of the warehouse or the company handling them.

Generally, however, storage involves the following steps:

- Receipt: the goods are received from the supplier and checked for expected quantity and quality. Any damage occurring during transport is also checked at this stage.

- Identification: each unit of goods is labelled so that it can be easily identified during storage.

- Classification: goods are classified according to their characteristics, such as fragility, size, weight, required temperature and so on.

- Packing: the goods are packed appropriately in order to prevent damage during storage.

- Actual storage: the goods are placed in storage in order to maximise space and minimise the risk of damage or degradation.

- Control: the goods are periodically checked for anomalies and to keep the inventory up-to-date.

- Order preparation: following an order, the goods are taken from the warehouse and packed in order to prepare them for shipment.

- Shipment and monitoring: the goods are loaded onto the means of transport, shipped to the final consignee and monitored throughout the journey until they are delivered.

Goods storage systems

There are different storage systems, and one of the most common and widely used is the shelving system: in this case, goods are placed on special shelf structures, made of various materials and sizes, depending on the type of goods to be stored. Shelving can be fixed or mobile and can be arranged on the floor or suspended, with the aim of optimising space.

Other forms of storage may involve the use of specific containers, such as crates, bins or pallets. In this case, goods are placed inside the containers, which can then be stacked or placed on trolleys or pallet trucks to facilitate movement within the warehouse.

In other cases, especially for large goods or goods of a special nature, dedicated storage areas, such as warehouses or open warehouses, can be used.

Generally speaking, each storage system has its own characteristics, so the choice of the most suitable system depends on several factors such as the specific requirements of the goods, the size of the warehouse and the budget available to the company.

If you have any doubts or questions about this, you can refer to us: contact us without obligation!